Is Particle Board Safe to Cut? (Safety Precautions)

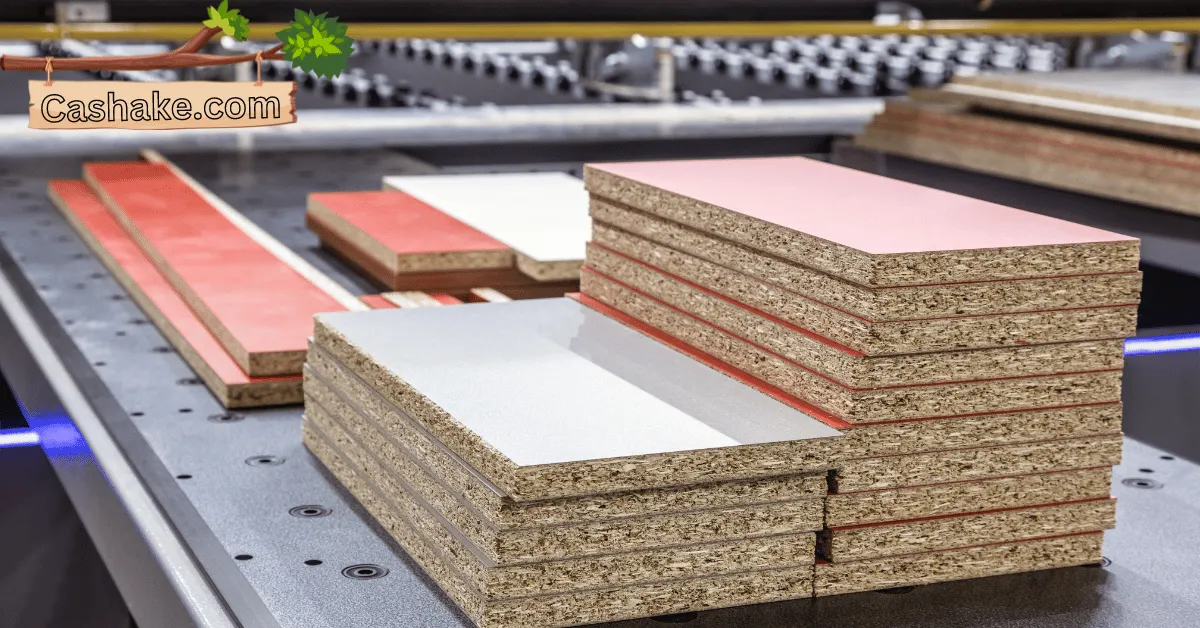

If you are thinking about cutting the particle board and you want to know the risks that are involved in cutting it then you should stop thinking and start reading this article. Particle board is used in furniture a lot and there are different ways to use it. But is particle board safe to cut?

Yes, particle board is safe to cut, but it doesn’t mean that you do not need any safety precautions. The particle board releases a specific kind of dust that can be severely irritating to your eyes and the respiratory system and for that reason, you must take safety precautions.

Well, without further ado, let’s dive deep into this article and learn more about cutting particle boards.

Table of contents

Is particle board safe to cut?

According to some sources, yes, you can cut the particle board safely because it has been getting cut for decades.

I am not saying that if other people can cut the particle board and nothing has happened to them it means nothing will happen to you.

But, if you follow the same precautions that other professional woodworkers take then it will be a piece of cake for you as well. When you are cutting the particle board it releases a specific kind of dust which is not good for your health.

For that reason, I would highly recommend that you wear the specific goggles and a dust mask so that you can save your eyes and your respiratory system from this dust.

So, many people have told me that there are specific kinds of resins that are used to make the particle board.

When those resins get cut they release formaldehyde toxins. This toxin is a carcinogen that causes throat cancer and other problems for you. This is the reason why it is not good for your health.

This toxin can cause headaches, allergies, and nausea. So, I hope you got my point. If you don’t then let me tell you.

The point is: It is safe to cut the particle board if you make it safe. It is your responsibility to wear the masks and goggles and also install the exhaust fan in your workspace.

When you will do that cutting a particle board will be a piece of cake and won’t get yourself unhealthy.

Read More: Does Particle Board Break Easily? A Comprehensive Guide & 11 Tips

What are the risks involved in cutting particle boards?

Alright, now it is time to talk seriously about the risks in some more detail. If you don’t know then let me tell you that there is an agency called IARC(International Agency for Research on Cancer), according to this agency the resins that are on the particle board contain formaldehyde gas which is a human carcinogen.

So while cutting the particle board this gas can get added to the air and and can increase the risk of inhalation.

If you breathe in this air for a long time it can cause health issues like respiratory problems, it will start irritating your skin and it can cause you certain cancers as well.

The next risk is while cutting the particle board it is also sure that small wood dust particles will also get added to your air and while working they can also go into your body by breathing them.

In this case, it will start irritating your eye, nose, and throat, and also it will cause you other diseases like asthma and allergies.

Now, let’s discuss skin irritation and eye injury a little bit more. The particle board has specific particles that are not good for human skin and it is also researched that there are chemicals that can cause your skin to be rash it can make it red and itching.

On the other hand, as I have told you the eyes are the most important parts of your body and while cutting particle board its particles can go into your eyes directly which is very painful.

Read More: How Do You Cut Particle Board Without Chipping It?

How to take care of the risks while cutting the particle board?

Now that you have learned about the risks, let’s learn how you will take care of these risks. So, first of all, please make your workspace a very well-ventilated area.

Now how will you do that? Well, for that you should always keep your windows and doors open and also use a normal fan so that the air in your workspace can pass away.

Also if you are working in a space where it is closed room then you should turn on the exhaust fan to pass all of the dirty air out and bring the fresh air in and by the way if you don’t have installed this fan then I would highly recommend that you should install it.

But on the other hand, if you are going to cut the particle board for the first time in your life and you won’t cut it next time in your life then you don’t need any kind of fan. You just cut the particle board in an open space.

Next, I would like to recommend that you wear a respirator or a mask. Do not wear the normal mask but wear the specific mask that is used for this kind of job.

I would recommend that you wear the N95 mask a specific respirator or any other higher-rating mask for effective filtration.

It is so important that before cutting the particle board or any other kind of wood you should sharpen the saw blades as much as you can.

Because the dull blades will cause your particle board to chip and cause the dust particles. Those particles can get inhaled easily. So before cutting this wood please use the sharp blades.

After cutting the particle board you should always clean up the dust. For this job, you can use a cloth which should be wet.

If you don’t want to wet it then make sure that you clean the area thoroughly with your normal cloth. Next, if you have a vacuum cleaner then install the HEPA filter in it and remove all of the dust from your workspace.

To protect your skin, you will be wearing full-sleeve clothes and you will be wearing boots as well. So now what remains is your hands, and for them, you should wear gloves which will protect you from the direct contact of particle board particles.

Now, the last thing that remains is eyes. To protect your eyes you should wear glasses or goggles. These glasses will protect your eyes from particle board.

If you take these tips and my recommendations then I am sure that you will be safe to cut the particle and you will also say that cutting the particle board is a piece of cake.

Read More: Is Particle Board Dust Harmful? 2 Surprising Truths

What are the best tools to use while cutting particle board to cut it safely?

Let me make it very easy for you for these tools that you should use while cutting the particle board.

| Tool | Purpose and Features | Blade/Accessory Recommendations |

| Circular Saw | Versatile and powerful for straight cuts. Use a sharp, fine-tooth blade for wood. For particle board, a 60-tooth or higher blade minimizes chipping and splintering. | – Sharp, fine-tooth blade for wood. 60-tooth or higher blade for particle board |

| Table Saw | Ideal for precise, repeatable cuts. A stationary blade and adjustable fence provide accuracy and control. Use a 60-tooth or higher blade with a fine-tooth design for particle board to prevent chipping and splintering. | – 60-tooth or higher blade with fine-tooth design for particle board |

| Jigsaw | Versatile for curved or irregular cuts. Use a jigsaw blade with 10 teeth per inch (TPI) or higher for smooth, clean cuts. | – Jigsaw blade with 10 TPI or higher |

| Handsaw | Useful for small, precise cuts. Choose a hacksaw or fine-tooth handsaw designed for cutting wood. | – Hacksaw or fine-tooth handsaw for wood |

| Safety Glasses | Protects eyes from flying particles and debris. | – N/A |

| Respirator | Minimizes exposure to formaldehyde fumes. Use N95 or higher rating for effective filtration. | – N95 or higher-rated respirator |

| Gloves | Protects hands from direct contact with particle board and potential irritants. | – N/A |

| Dust Mask | Alternative to a respirator for filtering airborne particles. | – N/A |

| Clamps | Secures particle board to workbench to prevent movement during cutting. | – N/A |

| Masking Tape | Applied along the cutting line to reduce chipping and splintering. | – N/A |

| Sandpaper | Smooth out rough spots on the edges of the cut particle board. | – N/A |

| Dust Collection System | Minimizes the spread of airborne particles by connecting to the saw. | – N/A |

If you want to take screenshots then you are allowed and also sharing is allowed there will be no copyright issues for you. These tools are the best ones that you should have while you are going to do this job.

Final Thoughts – Is it safe to cut particle board?

Well, my dear, it is indeed safe to cut the particle board if you cut it safely. There are some special tools and equipment that you should use while cutting the particle board like gloves, right blades, glasses for eye protection, a mask, and wearing full sleeve clothes.

If you follow the tips and recommendations that I gave you in this article then cutting the particle board will be easy for you. If you have any questions or thoughts then you can fill them up in the box below.

FAQs

Yes, wearing a respirator, preferably an N95 or higher-rated mask, is crucial while cutting particle board. This helps minimize exposure to formaldehyde fumes and protects against inhaling harmful particles released during the cutting process.

For those cutting particle boards for the first time in an open space, it is essential to ensure good ventilation. While a fan is not always necessary in an open environment, proper airflow by keeping windows and doors open is important to disperse dust and maintain a safe working environment.

To minimize chipping and splintering, it is recommended to use sharp blades in your cutting tools. For circular saws and table saws, opt for blades with 60 teeth or higher designed for particle board. Additionally, applying masking tape along the cutting line can help reduce the risk of chipping.

After cutting particle board, it’s crucial to clean up the dust effectively. Using a wet cloth or a vacuum cleaner with a HEPA filter is recommended. Wetting the cloth helps prevent particles from becoming airborne again, and using a vacuum with a HEPA filter ensures efficient dust removal.

While circular saws, table saws, jigsaws, and handsaws are recommended tools, other suitable alternatives include using a dust collection system to connect to the saw and clamps to secure the particle board to the workbench. These additional tools contribute to a safer cutting experience.