Which Edge Banding is Best? (Where and How to Buy it in 2024)

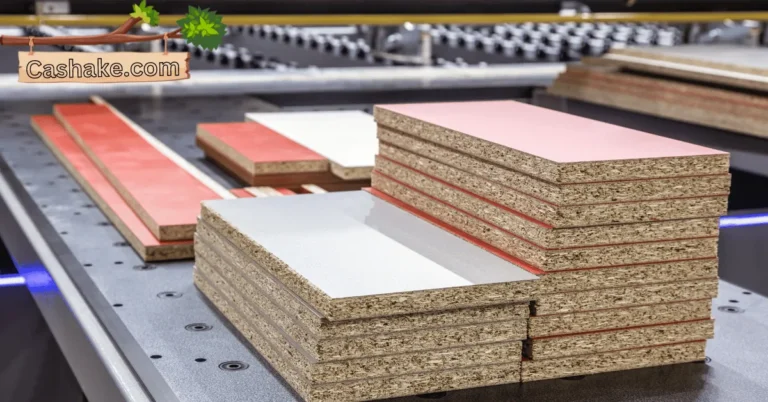

Edge banding is like the superhero cape for your wood-based projects! It’s a super-thin strip of material that you slap onto the edges of stuff like plywood, particle board, and MDF.

Why, you ask? Well, it’s here to save the day, protecting those edges from all the nasty stuff like moisture, rough handling, and chipping. Plus, it adds a touch of class, making your creation look polished and fancy.

Now, hold on to your tool belt because there’s a whole gang of edge banding types out there, each with its own set of superpowers and quirks.

Choosing the right one for your mission depends on what you’re building, the material you’re using, how tough you need it to be, and, of course, the look you’re going for.

In this guide, we’re diving deep into the world of edge banding. You’ll get the lowdown on all the different types in the league, how to pick the ultimate sidekick for your project and the nifty secrets of putting it all together.

We’ve even got the inside scoop on the best edge banding brands and where to grab ’em.

Whether you’re a rookie or a woodworking legend, this guide is your trusty sidekick, helping you choose the perfect edge banding for your next DIY adventure. And at the end of this guide your this question will be solved: Which edge banding is best? Let’s get crafting!

Key Takeaways

- Choose edge banding based on material, durability, and style.

- Consider thickness and width for a seamless finish.

- Match edge banding color to project aesthetics.

- Seek advice from woodworking experts and reviews.

- Iron-on veneer is beginner-friendly and budget-conscious.

- PVC excels in moisture-prone and high-traffic areas.

- ABS handles wear and curves but may cost more.

- Wood veneer offers a genuine, customizable wood look.

- Melamine is budget-friendly but less durable.

- PVC is the top choice for outdoor woodworking projects.

What are the different types of edge banding?

Let’s talk edge banding but in a more relaxed style.

So, you’ve got options when it comes to edge banding, and they each have their own thing going on:

- PVC Edge Banding: PVC, or polyvinyl chloride if you’re feeling fancy, is a champ. It’s tough, it can handle moisture like a boss, and it comes in all sorts of colors and finishes. You’ll often see it in kitchens, bathrooms, and furniture that gets a lot of wear and tear.

- Veneer Edge Banding: This one’s for the wood lovers. It’s like a thin wood jacket for your edges. You can match it up with your favorite wood species and even give it a stain or finish to make it blend right in.

- ABS Edge Banding: ABS is a plastic with muscles. It’s the go-to for commercial furniture and places that get a ton of traffic because it can take a hit and keep on going.

- Melamine Edge Banding: If you’re watching your wallet, melamine is a budget-friendly choice. It comes in various colors and finishes, but it’s not the toughest cookie in the jar.

And hey, there are some other options too:

- Acrylic Edge Banding: This one’s all about that shiny, modern look.

- Metal Edge Banding: Want a touch of glamour? Try metal in stainless steel, gold, or copper finishes.

- Paper Edge Banding: It’s thin, it’s cheap, and you’ll find it on disposable stuff like paper plates.

Now, how you put this stuff on depends on what you’re working on:

- Iron-On Edge Banding: Heat it with an iron, and it sticks like glue (well because it is glue).

- Pre-Glued Edge Banding: It comes with adhesive ready to go, just heat it or press it on during installation.

- Self-Adhesive Edge Banding: Peel and stick, the easiest way to go.

Remember, think about what you’re building. If it’s a kitchen counter, go for durability and moisture resistance. For furniture, make sure it looks good with the wood around it.

Once you’ve got the right edge banding and method, you’ll be on your way to project perfection. Happy banding!

How do I choose the right edge banding for my project? Which edge banding is best?

When it comes to picking the right edge banding for your project, let’s keep it simple:

Material: You’ve got options like PVC, ABS, wood veneer, and melamine. PVC is the all-rounder – tough, budget-friendly, and easy to work with.

ABS is like PVC’s flexible cousin, great for curved edges. Wood veneer gives you that real wood look but can be pricier. Melamine can take a beating in high-traffic spots.

Thickness: Edge banding comes in different thicknesses, from skinny 0.5mm to chunky 3mm. Go thicker for thin materials like plywood to avoid splitting. Use thinner banding for solid wood and keep it sleek.

Width: Think about the width about the thickness of your material. Wide banding covers plywood edges nicely, while narrower banding works for thick stuff like solid wood.

Color: You’ve got a rainbow of colors, wood patterns, and designs to choose from. Match your material or go bold for a standout look. Just remember, the color you pick is going to be front and center, so make it count.

Some bonus tips:

- If you’re stuck, ask your local woodworking pro for advice.

- Match veneer edge banding to your wood for a consistent vibe.

- Melamine edge banding should match your melamine’s color and finish.

- Your edge banding is like your project’s first impression, so make it a good one.

Once you’ve nailed down your edge banding game plan, you can stick it on using tools like a heat gun, hot iron, or an edge bander. Just follow the instructions that come with your chosen banding, and you’ll be on the right track.

What are the pros and cons of each type of edge banding?

Let’s break down these edge banding options in plain language:

PVC Edge Banding:

Good Stuff:

- Tough cookie: PVC can handle moisture like a champ, perfect for steamy spots like kitchens and bathrooms.

- Color party: It comes in lots of shades and finishes, so you can get creative.

- DIY-friendly: If you’re into DIY, PVC plays nice and is easy to work with.

Not-So-Good Stuff:

- Fake-out: It’s versatile but might not win any “most authentic wood” awards, so not ideal if you’re going for that natural look.

Veneer Edge Banding:

Good Stuff:

- Wood wonder: Veneer brings genuine wood vibes to the party, and you can dress it up with stains and finishes.

- Mix and match: You can match it up with your main wood for a seamless look.

Not-So-Good Stuff:

- Wallet warning: It can be pricier than some others, so keep an eye on your project budget.

- Moisture moods: It’s not as water-loving as PVC, so maybe not the best pick for super humid spots.

ABS Edge Banding:

Good Stuff:

- Tough cookie, part two: ABS can handle some serious wear and tear, perfect for places that get a workout.

- Flex appeal: It’s all about the curves, making it a design superstar.

Not-So-Good Stuff:

- Look vs. Durability: It’s durable but might not give you that natural wood vibe, which could be a deal-breaker for style enthusiasts.

- Price check: ABS can hit your wallet harder than PVC or melamine.

Melamine Edge Banding:

Good Stuff:

- Budget-friendly: Melamine won’t break the bank, making it a thrifty choice.

- Variety show: It comes in a bunch of colors and finishes, so you’ve got options.

Not-So-Good Stuff:

- Handle with care: Not as tough as PVC or ABS, so think twice for high-traffic zones.

- Looks department: Like PVC, it might not win the beauty contest against wood veneer.

Remember, pick your edge banding buddy based on your project’s needs. Think about the material, how much it’ll get used, the look you want, and your budget. Each type has its quirks, so choose the one that fits your DIY adventure best.

What are the best edge banding brands?

When you’re on the hunt for the coolest edge banding brands, think of variety, quality, and keeping your wallet happy. In the edge banding world, some big names have earned their stripes, and you might wanna check them out:

- Rehau

- Richies

- E3

- Huali

- Pegasus

- Homag

- Biesse

- SCM

- IMA

- KDT

These folks know their stuff and bring you all sorts of edge banding goodies, from PVC to wood veneer to acrylic. And they’ve got thickness options and more colors than a crayon box to suit every project flavor.

Now, let’s get down to business. Your first move is to think about what material you’re rolling with.

- PVC: It’s a crowd-pleaser for most woodworking gigs. Tough, budget-friendly, and user-friendly.

- Wood Veneer: Go here for that natural, woodsy look.

- Acrylic: If you’re aiming for a glossy finish that shines like a star, acrylic’s your ticket.

Next, match the thickness of your edge banding to your material. Easy math: If you’re rocking a 1/2-inch thick plywood, grab a 1/2-inch thick edge banding.

Lastly, let’s talk colors. Edge banding comes in more shades than you can count, so pick one that’s in sync with your project’s style.

A couple of tips to help you out:

- Check out what folks are saying in customer reviews to suss out product quality and brand service vibes.

- Don’t hesitate to tap into the wisdom of your woodworking crew – friends, family, or fellow DIYers might have some golden brand recommendations.

- And when you’re ready to shop, hit up trusted retailers to make sure you’re getting top-notch gear that lives up to the hype.

So there you go, now you’re all set to rock your edge banding journey.

Where to buy edge banding?

Getting your hands on some edge banding in the good ol’ USA is a breeze. You’ve got options, whether you’re a click-and-shop online kind of person or you prefer the tactile experience of a physical store. Check it out:

Online Stops:

- Amazon: The one-stop shop for just about everything.

- Edgeband USA: They’ve got “edge” in the name, so they mean business.

- Woodworker’s Supply: Where woodworking dreams come true.

- Rockler Woodworking and Hardware: Rock your DIY projects with their gear.

- Woodcraft: Crafty wood solutions at your fingertips.

In-Person Hangouts:

- Home Depot: The home improvement HQ.

- Lowe’s: Another big player in the DIY world.

- Ace Hardware: The helpful place for hardware needs.

- Menards: Making big projects possible.

- Local woodworking stores: Your neighborhood’s hidden gem.

Now, let’s get savvy about your edge banding game:

- Types: There’s PVC, wood veneer, melamine, and more. Pick the one that plays nicely with your project.

- Thickness: Go a tad thicker than your material for a polished look.

- Colors and Patterns: From matching to contrasting, edge banding has style. You choose the vibe.

- Expert Tips: Don’t hesitate to chat with the store folks if you’re in DIY limbo. They’re there to help you win at woodworking.

So there you have it, a handy guide to scoring the right edge banding. Compare, explore, and get that project looking sharp!

Which edge banding is best for beginners?

If you’re just starting in the world of edge banding, here’s the scoop: iron-on veneer edge banding is your buddy.

It’s super beginner-friendly, and you won’t need any fancy gadgets. Plus, it won’t break the bank.

Here’s the drill for applying it: cut it to the right size, then grab your trusty iron. Give it a good press along the edge of your wood project.

The heat works its magic, melting the adhesive on the back of the banding, and boom, it’s bonded to the wood. Easy-peasy, right?

Which edge banding is best for plywood?

Picking the right edge banding for your plywood gig is like choosing the perfect tool for the job – it all depends on what you’re after.

Wood Veneer Edge Banding: This one’s all about class. It’s like putting on a fancy suit for your plywood. With different wood species and finishes, it’s your ticket to a polished, upscale look.

Melamine Edge Banding: Versatility is the name of the game here. Melamine rocks a rainbow of colors and finishes and can handle the hustle and bustle of high-traffic areas. Plus, it’s a breeze to clean. Bonus: it won’t break the bank.

PVC Edge Banding: PVC is like the superhero of edge banding. It can take on water like a champ, so it’s your go-to for moisture-prone projects. It’s tough and low-maintenance but might cost a tad more than melamine.

So, here’s the deal – if you’re chasing that sophisticated vibe, go wood veneer. But if durability and easy cleaning are top of your list, melamine and PVC have your back. And if you’re watching those pennies, melamine’s the budget-friendly champ.

Pick your edge-banding superhero based on what your plywood project needs and you’ll be golden.

Which edge banding is best for high-traffic areas?

Alright, let’s talk edge banding that can handle the hustle and bustle of high-traffic spots. We’re looking for the tough cookies here, and two names pop up: PVC and ABS edge banding.

PVC Edge Banding: This one’s made from polyvinyl chloride, a fancy thermoplastic resin known for its hardcore durability. It laughs in the face of heat, moisture, and chemicals. Plus, it’s a budget-friendly champ and a breeze to put on. Perfect for places like kitchens, bathrooms, and busy offices.

ABS Edge Banding: Meet PVC’s cousin, crafted from acrylonitrile butadiene styrene. It’s like PVC’s twin in toughness but might cost you a bit more and require a tad more skill to apply. Bonus points for being eco-friendly – it can be recycled or safely incinerated.

When you’re on the hunt for edge banding that can handle the heat (literally) of high-traffic areas, here’s the checklist:

- Durability: It should laugh at wear and tear, plus stand strong against heat, moisture, and chemicals.

- Easy-Peasy: You want something that won’t make you pull your hair out during application, even if you’re not a pro.

- Budget-Friendly: Keep an eye on the price tag because edge banding comes in all flavors.

- Looks Matter: Go for a color and finish that vibes with your furniture’s overall style.

For high-traffic spots, my vote goes to PVC or ABS edge banding. They’re the durability dream team. PVC is your wallet’s best friend, while ABS gets eco-points. Your choice comes down to budget and personal flavor.

Which edge banding is best for outdoor use?

When you’re decking out your outdoor space and need the lowdown on edge banding, here’s the scoop: it’s all about beating the elements. You want something that can handle water, moisture, the blazing sun, and even the chills.

PVC (Polyvinyl Chloride): This is the rock star of outdoor edge banding. It laughs in the face of all the outdoor challenges. It’s tough, affordable, and a piece of cake to work with. Perfect for all sorts of outdoor projects.

But hold on, there are a few other contenders worth a mention:

Polyester: If you’re an eco-warrior, polyester is your buddy. It’s like PVC’s green cousin, durable and ready to face all weather conditions.

Acrylic: If style is your game, acrylic brings the party. It comes in a rainbow of colors and finishes, and it’s not just weather-resistant – it’s also scratch and fade-resistant. Hello, good looks!

Solid Wood: Now, this one’s the fancy pants. Solid wood is the priciest option, but it’s the king of durability and style. If you’re going high-end with your outdoor furniture, this is where it’s at.

So, here’s the deal: if you want a safe bet, go PVC. But if you’re all about the environment, polyester’s calling your name. For style mavens, acrylic is your jam.

And if you’re ready to splurge for that top-tier look and feel, solid wood’s got your back. It all comes down to your project needs, budget, and design dreams.

Important FAQs

Edge banding is a thin strip of material applied to the edges of wood-based projects like plywood and particle board. It’s important because it protects edges from moisture, rough handling, and chipping while adding a polished look.

When selecting edge banding, consider the material (PVC, ABS, wood veneer, melamine), thickness (0.5mm to 3mm), width (relative to material thickness), and color or pattern to match the project’s style and needs.

Pros: PVC is moisture-resistant, versatile in colors and finishes, and DIY-friendly. Cons: It may not provide the most authentic wood look.

Wood veneer edge banding offers a genuine wood appearance and can be customized with stains and finishes. However, it can be pricier than other options and is less water-resistant.

ABS edge banding is durable, making it ideal for high-traffic areas. It excels at curved edges but may not provide a natural wood appearance and can be more expensive.

Melamine edge banding is budget-friendly and comes in various colors and finishes. However, it may not be as durable as PVC or ABS, making it better suited for less demanding applications.

Final Thoughts

So, wrapping it up, picking the perfect edge banding for your woodworking gig is kind of a big deal. It can seriously make or break the look and functionality of your project.

We’ve covered all the ins and outs of edge banding types, what’s good and not-so-good about them, and even dropped some cool brand names you should check out.

Now, here’s where you come in! We’re super curious about your edge-banding adventures. Have you given any of these types or brands a spin?

Do you have any neat tricks up your sleeve you’d like to share with your fellow woodworking pals? Just drop your thoughts down below, and let’s get this conversation rolling.

And hey, if you found this article handy, don’t keep it a secret. Share the woodworking love with your buddies, family, or anyone who’s into some DIY action. Together, we can all step up our woodworking game. Happy crafting, folks!

Why is My Iron on Edge Banding Not Sticking? (Solved)(2023)

Having explored this article, your next must-read is “Why is My Iron on Edge Banding Not Sticking? (Solved)(2023)” for expert solutions to common edge banding challenges.